product overview

lc type vertical long shaft pump is a series of advanced and mature products developed on the basis of absorbing the advanced design and manufacturing experience at home and abroad, combined with the market demand. transport clear water, sewage with certain solid particles (such as iron filings, sand, coal powder, etc.), corrosive industrial wastewater and sea water; the temperature of the conveying liquid shall not exceed 80 ℃. it is widely used in primary water treatment plant, sewage treatment plant, metallurgy and iron and steel industry (especially for the transportation of oxide scale in the whirlpool of the industry), power plant, mine, municipal engineering and farmland water conservancy engineering.

model meaning

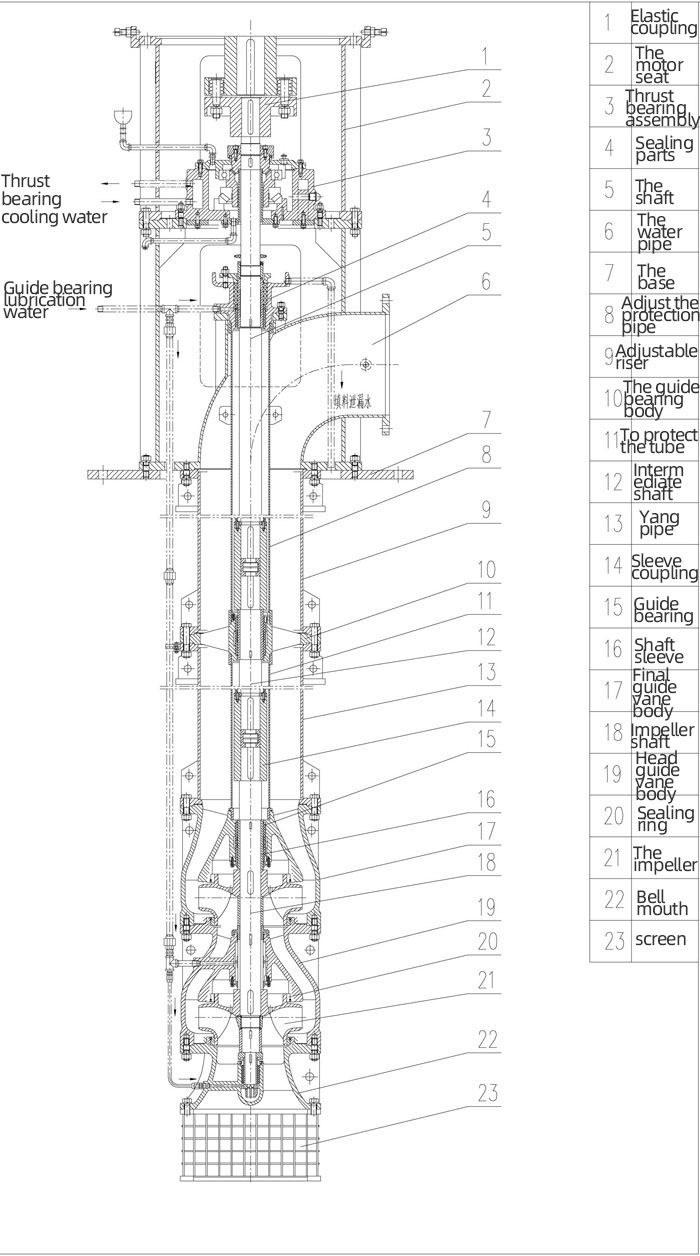

structural drawing

product characteristics

lc type vertical long shaft pump has vertical inlet downward, horizontal outlet, single foundation installation, direct connection between pump and motor; from the top of motor end, the pump rotates counterclockwise, and its main features are as follows:

1. the hydraulic design software is used to optimize the design, the performance is superior, and the abrasion resistance of impeller and guide vane is fully considered, so that the service life of vulnerable parts such as impeller is greatly improved; the product runs stably, safely, reliably and efficiently.

2. the inlet of the water pump is equipped with a filter screen, and the size of the opening is appropriate, which not only effectively prevents the large particles from entering the pump and damaging the water pump, but also ensures that the net water inlet area is more than 3.5 times of the sectional area of the lifting water pipe, so as to minimize the inlet loss and improve the efficiency of the water pump.

3. the impeller uses the balance hole to balance the axial force. the front and rear cover plates of the impeller are equipped with replaceable sealing rings to protect the impeller and pump body. the seal ring adopts a special weir type structure, which can effectively prevent the oxide scale or other impurities from sinking to the gap inlet of the seal ring after the pump stops, greatly improving the service life of the seal ring and the impeller.

4. the pump intermediate shaft, water lift pipe and guard pipe are multi section. the intermediate shaft adopts sleeve coupling patented technology. the radial coaxiality is ten times higher than other coupling methods, and the vibration of the whole machine is reduced by more than 70%. the number of water lift pipes can be increased or decreased according to the user's needs, and adapt to different underwater depth. impellers and guide vanes can be multi-stage to meet different lift requirements.

5. the lifting pipe of water pump is connected by flange, with guide bearing in the middle. the guide bearing of water pump shall be reinforced filled with polytetrafluoroethylene or canadian cylon bearing, or nitrile rubber (for medium temperature higher than 55 ℃), and the shaft shall be protected by protective pipe. when transporting clear water, the protective pipe can be cancelled, and the guide bearing does not need to be connected with cooling lubricating water; when transporting sewage, the guide bearing must be connected with cooling lubricating water. for places where there is no clean water or the cost of clean water is high, special structure can be added, and the guide bearing can be cooled and lubricated after the medium transported by the pump is filtered or separated by sedimentation. control elements such as flow and pressure relay can be added to the lubricating water system. when the water supply before startup is lower than the rated water supply, the pump can not be started. when there is water shortage due to some reason (pipeline blockage) during operation, the relay will send alarm signal, the buzzer in the control room will sound, and the red light will alarm. at this time, the valve of the bypass system can be opened to supply water to ensure sufficient water supply, at the same time, the fault can be repaired. this control system can realize remote control.

6. the residual axial force of the pump and the weight of the rotor parts shall be borne by the thrust bearing in the motor seat or the motor with thrust bearing. the thrust bearing is lubricated with thin oil and cooled by external water. the thrust bearing can be embedded with temperature control elements.

7. the shaft seal of the pump is a packing seal. replaceable shaft sleeve is installed at the shaft seal and guide bearing to protect the shaft. the axial position of the impeller is adjusted by the adjusting nut on the upper end of the bearing component or in the pump coupling, which is very convenient.

8. the water pump can be equipped with a control cabinet, which can automatically start and stop according to the liquid level, overload alarm, real-time remote monitoring and other functions, and can realize the remote centralized control of multi pump networking. the pump with diameter larger than 500mm is equipped with automatic exhaust system.

performance parameter