product brief

xbd / g-hrzl axial flow deep well fire pump (long shaft deep well fire pump, vertical axial flow deep well fire pump, electric vertical long shaft turbine fire pump, diesel engine deep well long shaft fire pump) produced by shandong hai rui zhonglian fluid technology co., ltd. is a vertical long shaft fire pump optimized for the safety reliability and performance of the original hrzl / x vertical long shaft pump, especially suitable for industrial and mining enterprises the performance and technical conditions of the pump meet the requirements of gb6245-2006 fire pump. the products have been tested by the national fire equipment quality supervision and testing center, and passed the appraisal of new products in shandong province, and obtained the approval certificate of fire products in shandong province. the fire inspection reports such as cnca-c18-03:2014 rules for the implementation of compulsory product certification fire fighting equipment products, cccf-mhsb-08 rules for the implementation of compulsory product certification fire fighting equipment products fire fighting water supply equipment products (i) are qualified.

model description

xbd new series vertical long shaft fire pump has unique advantages:

1. the advanced hydraulic model and mechanism design of american company are introduced. the ashland process is adopted to know the core and epoxy coating of blade passage. the imported human-made bearing is used to reduce the bearing loss, which can withstand 120 ℃ high temperature. the german iger bergman machine seal is durable, acid and alkali resistant, with high efficiency and long service life.

2. adopt the sanding ring device, labyrinth structure to prevent sand from entering the bearing

3. the stainless steel runner impeller made of non welding and integral casting is adopted, the anti winding design is unblocked; the precision turning and grinding of stainless steel pump shaft, the radial run out of the shaft is controlled within 0.13mm of the american standard, the pump runs stably, and the noise is low.

4. qt450 ductile iron, ht250 and other stainless steel corrosion-resistant materials are selected to meet the user's various special operating conditions and technical requirements.

5. the product has high efficiency, the pump head is completely immersed in the liquid, and there is no self-priming time. when the pump is started, the water supply is pressurized synchronously;

6. the impeller of the pump can be directly started without bottom valve, water filling and shaft vacuum, which is very convenient and reliable; 3. it can be directly installed on the water tank, only two support beams and channel steel beams can be fixed, without water absorption pipeline;

7. the maximum diving and water absorption height of the pump can reach about 10 meters, with vertical structure, small floor area and less capital investment.

8. the submerged length can be customized according to the depth of the pool, so as to ensure that the lowest water level can be pumped.

working principle and structure description

working principle of the pump: the motor drives the impeller working under the liquid through the shaft, the fluid obtains energy through the impeller, and then it changes direction through the space guide vane, rises vertically along the channel between the inner and outer pipes, and flows out horizontally through the outlet elbow.

the pump is composed of a central rotating body and a pump body. the rotating body is composed of impeller, shaft, sleeve type rigid coupling (coupling and coupling sleeve), bearing, elastic pin coupling, etc. the pump body is composed of filter screen, space guide vane, outer tube, inner tube, rubber bearing frame, base, water outlet elbow, bearing body, motor seat, etc.

the whole part of the pump is connected with the water outlet elbow, which is fixed by the bottom plate. the double rolling bearing and the intermediate guide bearing above the rotating part are connected with the water outlet elbow, which is fixed by the bottom plate. the double rolling bearing above the rotating body part, the middle guide bearing part and the lower guide bearing part in the space guide vane support. at the same time, clean lubricating water can be injected into the lubricating water pipe on the side of the stuffing box (the inner pipe can be cancelled when the medium is clear water), and the lubricating and cooling guide bearing (pfc) can be continuously lubricated along the flow channel area between the inner pipe and the shaft. this is the key to the normal operation of the vertical long shaft pump in the transportation of the medium containing solid particles and other adverse conditions.

material of main parts

structural drawing of pump

partial performance parameters of pump

in the design of the pump, considering the structural characteristics of the long shaft pump, the use conditions of the user, the requirements for reliability and the market demand, the diameter of the pump is planned to be 100mm ~ 300mm; at the same time, due to the structural characteristics of the pump itself, in order to ensure the operation reliability of the product, the maximum submerged length of each diameter is limited, as shown in the table below:

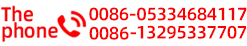

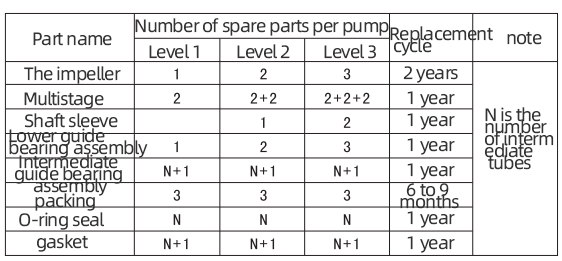

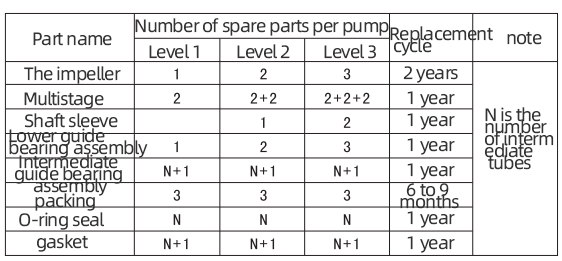

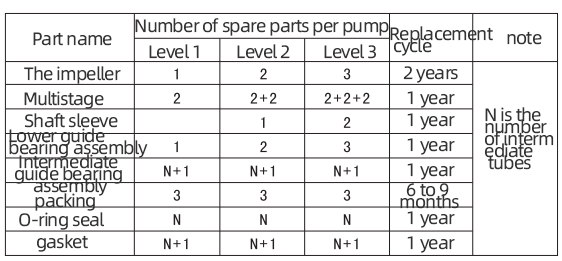

note: the maximum submerged length l1 refers to the length from the installation base surface to the bottom surface of the filter screen, which can be customized beyond the scope. list of spare parts for water pump

complete supply scope

1, pump

2, motor

3. coupling, coupling sleeve

4. base and foundation bolt

5. lubricating cooling water pipe, oil level gauge

6. spare parts (according to customer needs)

instructions for ordering

1. in order to correctly select the pump specifications, parts and materials according to the use conditions, the user shall provide us with the required flow and lift, liquid depth, medium conditions and other relevant information when ordering.

2. if there are special requirements for the prime mover, the user shall explain the site conditions.

3. if the user has other requirements for shaft seal and leakage, it shall be specified when ordering.

4. if the long shaft fire pump needs lubricating cooling water, the lubricating cooling water and its water supply system shall be provided by the user. the operator shall communicate with the user about the pressure and flow of the lubricating cooling water supply to avoid unnecessary misunderstanding.

5. special hoisting equipment shall be used for loading and unloading of long shaft pump to avoid pump damage due to improper hoisting.

this long shaft fire pump has passed the national cccf certification